CNC Machining Service

Why Choose Us

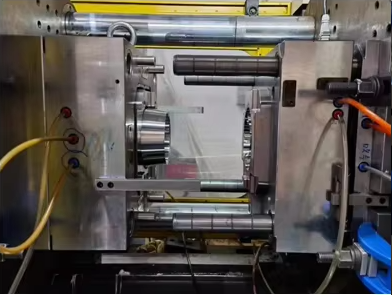

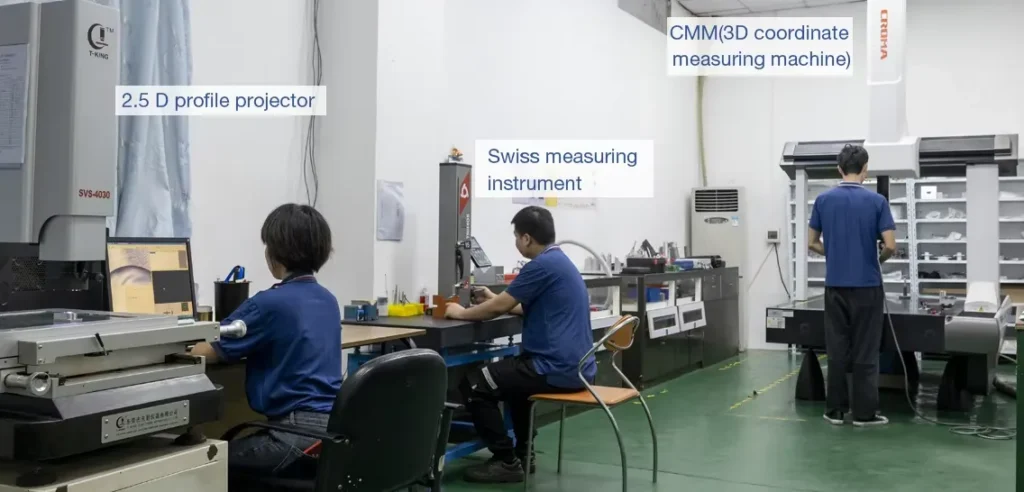

✅1、Precision That Powers Your Production

Our CNC machining hits tolerances as tight as ±0.001mm, ensuring every component integrates seamlessly into your assembly lines. Advanced metrology tools validate consistency across batches, eliminating costly reworks for your production chain.

✅2、On-Time Delivery, Every Time

We sync with your production schedules using lean manufacturing workflows, guaranteeing 98% on-time delivery. Flexible capacity scaling means we adapt to rush orders without compromising quality—keeping your operations on track.

✅3、Cost Efficiency for Long-Term Gains

Optimized tooling strategies and material utilization cut waste, translating to 15-20% lower costs vs. competitors. Transparent pricing with no hidden fees lets you plan budgets reliably, boosting your bottom line.

✅4、Engineering Partnership Beyond Machining

Our technical team collaborates on DFM (Design for Manufacturability) to refine your specs, reducing lead times and enhancing part performance. We’re invested in your production success, not just one-off orders.

Company Profile

We’re a team focused on CNC machining, built to help businesses like yours get the precision parts they need—no confusing jargon, just reliable results.

For over 15 years, we’ve worked with companies across industries: from automotive and electronics to medical devices and industrial equipment. Whether you need parts made from metal, plastic, or other materials, our CNC machines (think high-tech tools that carve, cut, and shape with pinpoint accuracy) handle it all.

What matters most to us? Making your life easier. We start by listening—so we understand exactly what you need, from tight deadlines to specific sizes or finishes. Then, our skilled team uses top-tier equipment and strict checks at every step to make sure each part is right, first time.

We don’t just make parts; we build partnerships. Small orders or large runs, simple designs or complex ones—we’re here to deliver on time, on budget, and without the hassle.

Ready to get your project moving? Let’s talk.

Materials for Custom CNC Machining

Our machining services work with lots of different materials—everything from metals to plastics.

Depending on what you need to make, you can pick from more than 50 strong, production-ready materials that Ai CNC has.

Want to see which materials we use for CNC machining? Check out our list.

And if you’ve got special needs or ideas, just get in touch—we’re happy to talk about them!

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Lead Time: < 10 days

Wall Thickness: 0.50 mm

Tolerances: ±0.01mm (±0.0004″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Lead Time: < 10 days

Wall Thickness: 0.50 mm

Tolerances: ±0.01mm (±0.0004″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Lead Time: < 10 days

Wall Thickness: 0.50 mm

Tolerances: ±0.01mm (±0.0004″)

Max part size: 200 x 80 x 100 cm

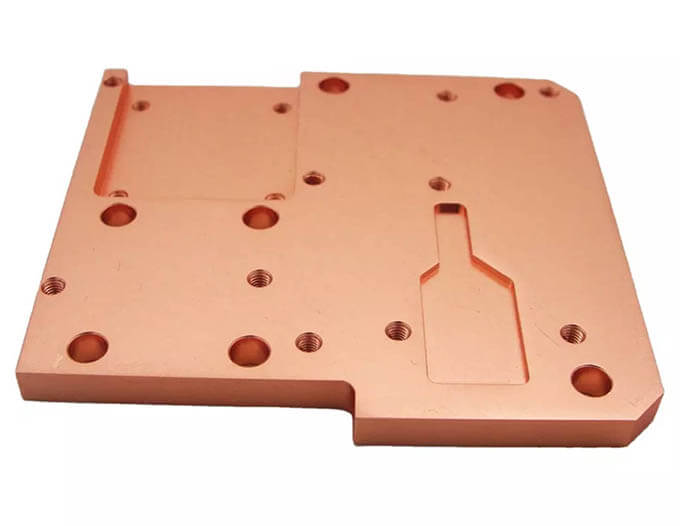

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Lead Time: < 10 days

Wall Thickness: 0.50 mm

Tolerances: ±0.01mm (±0.0004″)

Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Lead Time: < 10 days

Wall Thickness: 0.50 mm

Tolerances: ±0.01mm (±0.0004″)

Max part size: 200 x 80 x 100 cm

Plastic

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |